FIBC with 2 loops can be manufactured in various sizes based on customer specifications. This kind of bags can be manufactured with coated or uncoated fabric. The advantage of a discharge spout is that the material can be emptied from the bag without the bag being destroyed and it can therefore be used as multiple trip bag. The advantage of a filling spout is that it is possible to close and seal the inlet of the bag so that any dust from powder or like materials are not spread out in the environment where its filled. The filling and discharge spout can be adapted for filling/emptying device which also simplifies the assembly of the filling and discharge spout. The advantage of the 2 loop bags is that it can be lifted with hooks or any type of forklift machines. This design is very cost-effective where large volumes are handled and packaged. The bags are very easy to stack which provides a efficient storage. We can also offer big bags with 2 loops with an inner bag made of LDPE.

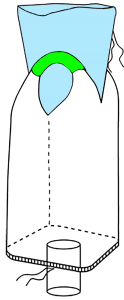

FIBC with filling spout and discharge spout

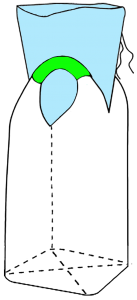

FIBC with filling spout and flat bottom

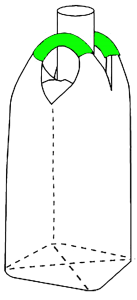

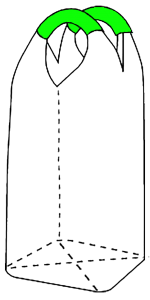

FIBC with open top and discharge spout

FIBC with open top and flat bottom

FIBC with skirt and discharge spout

FIBC with skirt and flat bottom